Pallet Wrapping Machine Servicing,

Repairs & Maintenance – UK Wide

Excelerate provides expert service engineers across the UK for all major wrapping machine brands. Emergency call-outs, preventative maintenance, and free film audits to reduce running costs and minimise waste.

- ✓ Free Film Audit — typical savings 20-50%

- ✓ Nationwide Engineers & OEM Parts

- ✓ Emergency Repairs & 24/7 Callout (contract customers)

- ✓ Trained Support for All Major Brands (Robopac, Lantech, SIAT, etc.)

Nationwide On-Site

Service Engineers

Our on-site pallet wrapper repair engineers attend UK mainland sites for pallet wrapping machine servicing and stretch wrapper repairs.

- ✓ Services available throughout London, Manchester, Birmingham, Bristol & Glasgow, and UK-wide

- ✓ Telephone support and technical video call diagnosis

- ✓ Trained engineers for Lantech, Robopac, IBIS, Orion, and other major brands

- ✓ Preventative maintenance plans to stop costly breakdowns

- ✓ Emergency 24/7 support available for contract customers

Why Service Your

Pallet Wrapper?

Downtime from a failed pallet wrapper can halt your dispatch process, causing missed deadlines, wasted film, and costly manual workarounds.

Most manufacturers recommend servicing annually (every 12 months) or bi-annually for machines in high use. Planned servicing and preventative maintenance keep your stretch wrappers reliable, efficient, and compliant.

- ✓ Running reliably at full capacity

- ✓ Using the correct film tension (avoiding waste and product damage)

- ✓ Safe for operators, compliant with health & safety standards

- ✓ Longer-lasting — extending the life of rollers, belts, and motors

- ✓ Customers moving to bi-annual plans report 40% fewer breakdowns

Broken Chain

Fault discovered during an Excelerate service visit — left untreated, this could lead to machine failure and costly downtime.

Worn Rollers

Routine inspection identified worn bearings, preventing further wear and avoiding expensive repairs down the line.

Film Roped Around Components

Film jamming inside key components, identified and fixed by Excelerate engineers during a routine service call.

What We

Service

Our engineers specialise in packaging and wrapping equipment, delivering expert servicing and repairs across a wide range of machinery:

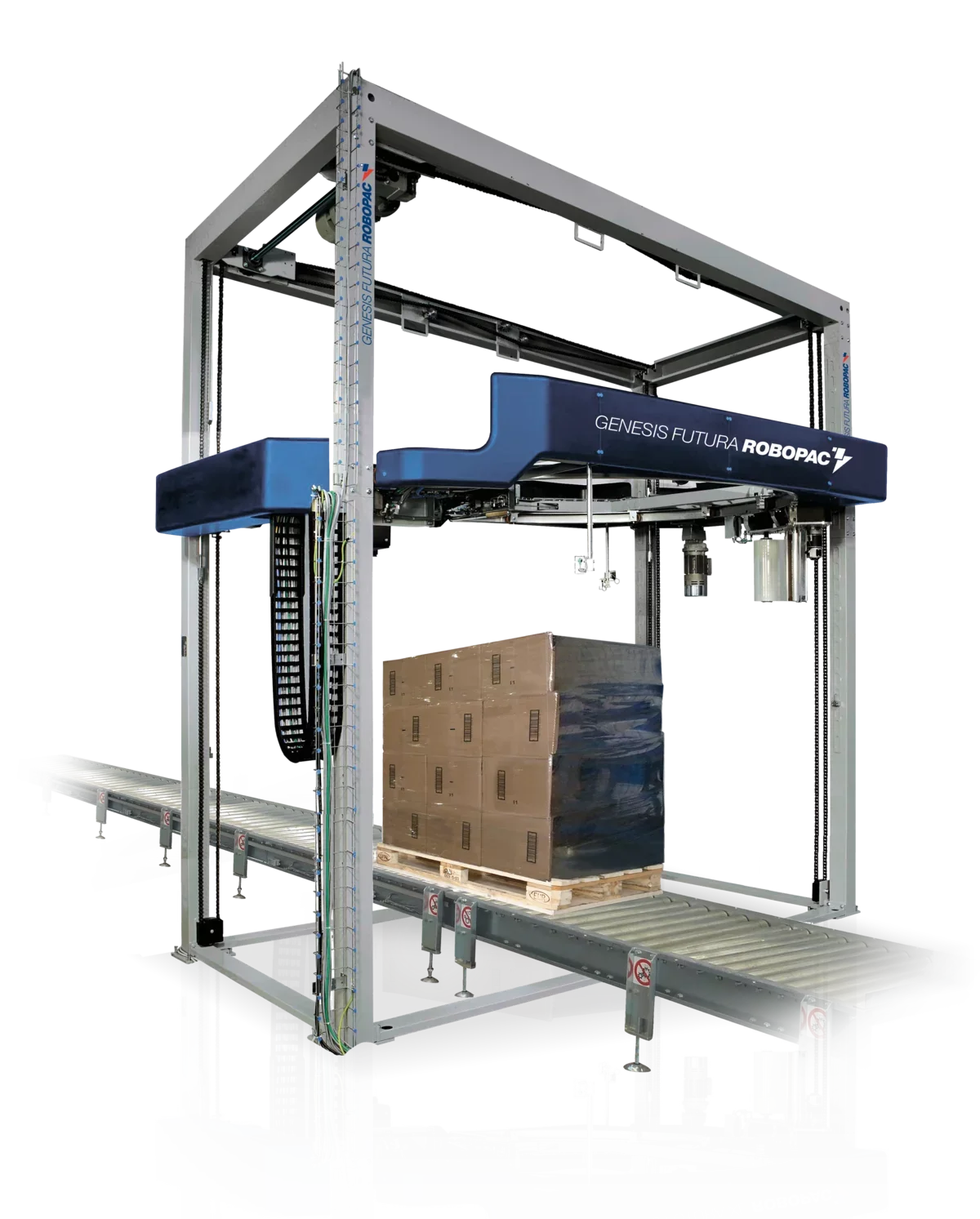

Rotary Arm Wrappers

Heavy-duty rotary arm pallet wrappers kept running smoothly with regular Excelerate servicing.

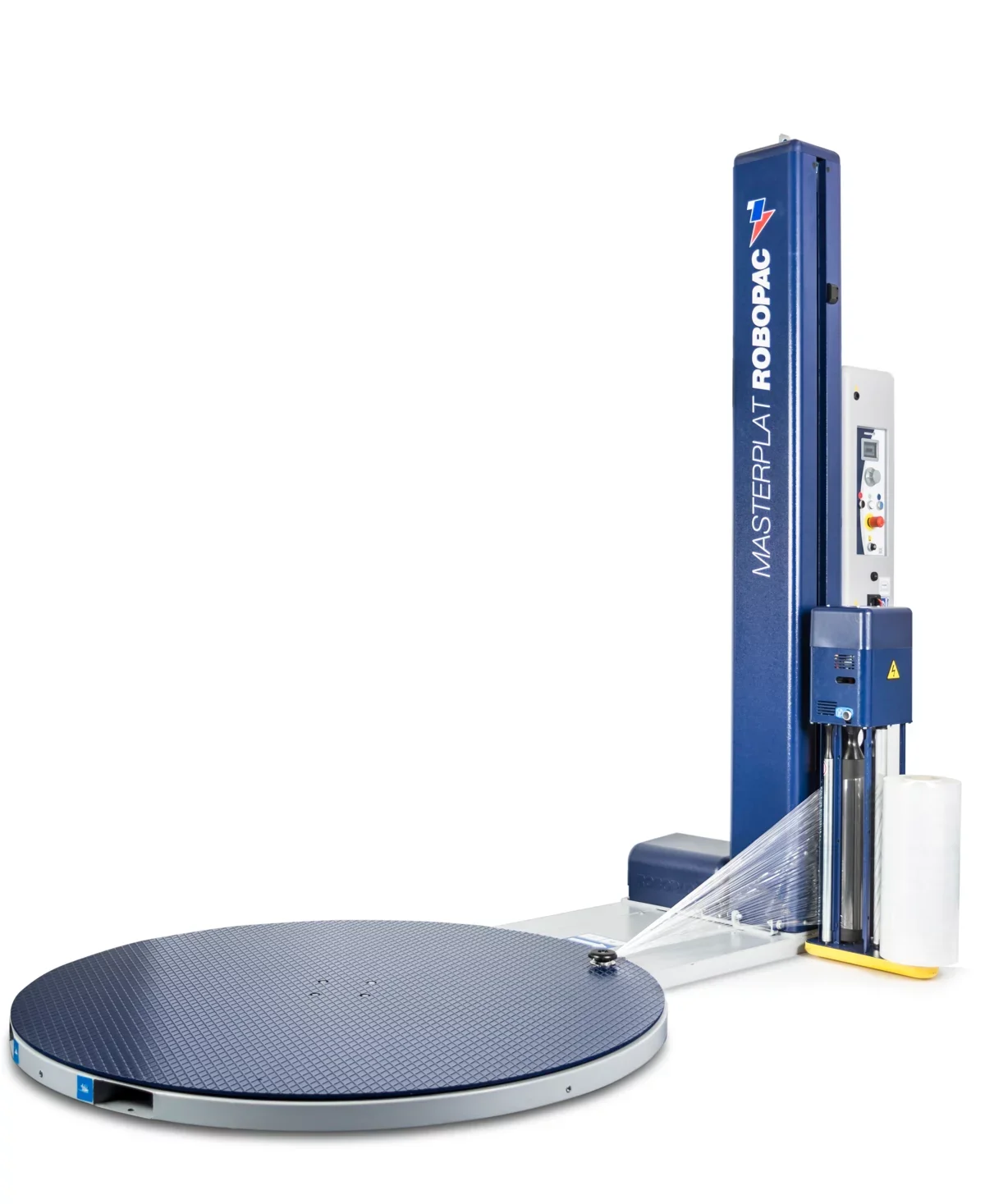

Turntable Wrappers

Turntable pallet wrappers serviced to ensure reliable wrapping and reduced film waste.

Robot Wrappers

Mobile robot pallet wrappers serviced to maximise uptime and operator safety.

Conveyor Systems

Belt and roller conveyors maintained to keep production moving without costly stoppages.

Heat Sealers

Continuous and impulse heat sealers serviced for safe, efficient packaging performance.

Paper Tape Machines

Water-activated and gummed tape dispensers serviced for reliability and precision.

Spiral Wrappers

Spiral wrapping machines inspected and maintained by specialist Excelerate engineers.

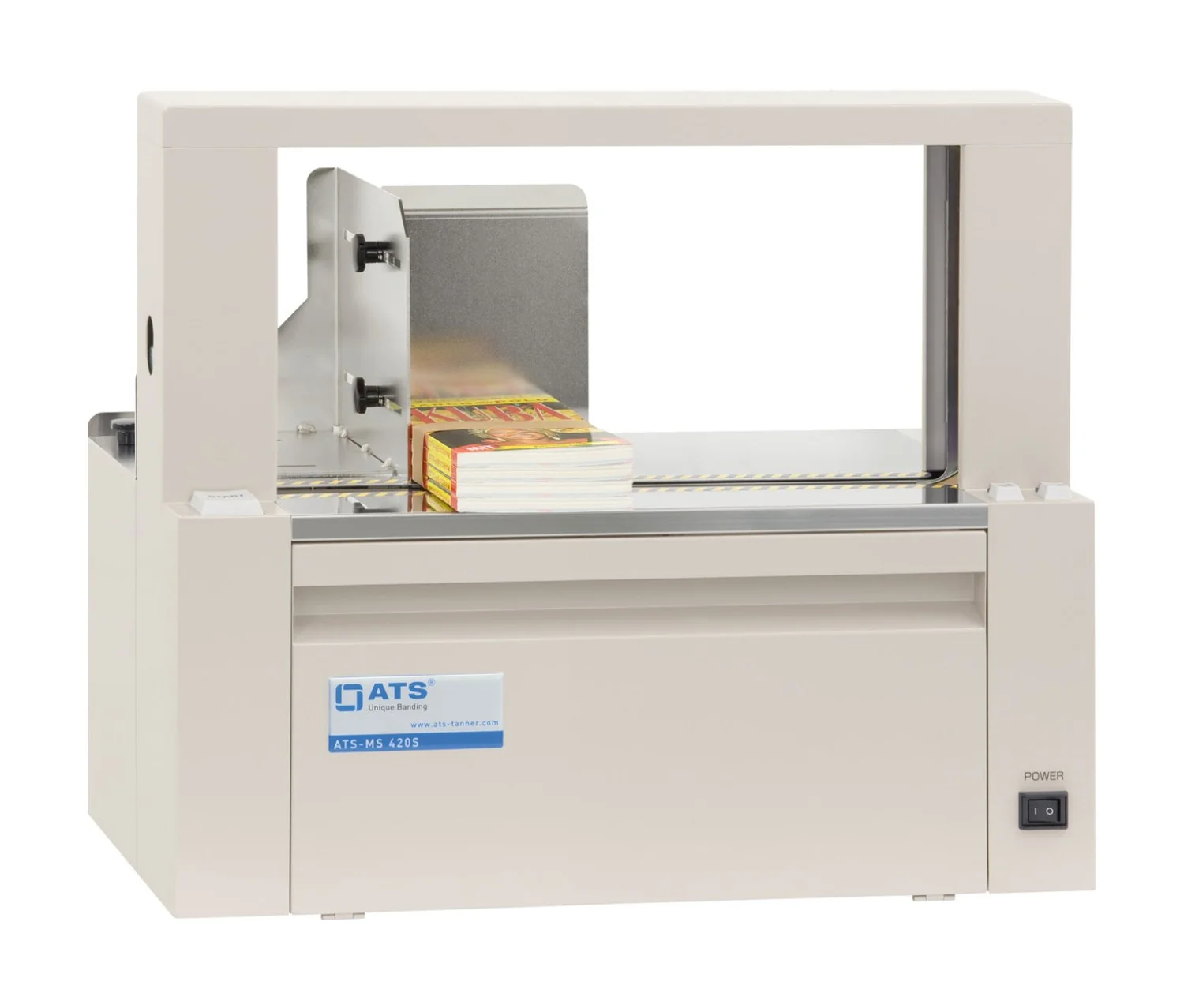

Banding Machines

Automatic and semi-automatic banding machines serviced for high-speed packaging lines.

We can also service bespoke machinery or other specialist requests — speak to our team to discuss your equipment.

Stretch Wrapper

Servicing

Stretch wrappers are complex machines — when they fail, your packaging process stops. Our engineers are trained across leading stretch wrapper brands and provide both preventative maintenance and on-demand repair.

Common Stretch Wrapper Faults We Resolve

- ✕ Film snapping or tearing during wrapping

- ✕ Carriage not raising or lowering correctly

- ✕ Incorrect pre-stretch settings

- ✕ Safety guard or sensor errors

- ✕ Height detection errors

- ✕ Turntable or arm motor issues

- ✕ Gearbox issues

- ✕ Noises in operation

We also supply and fit OEM spare parts to guarantee long-term performance and reliability.

Preventative

Maintenance Plans

Every site is different, which is why we offer custom service plans tailored to your usage and workflow.

| Annual / Bi-Annual | Quarterly | Tailored SLA |

|---|---|---|

| Low-usage machines | Heavy-use or 24/7 sites | Flexible — built around your operation |

| 1–2 visits per year | 4 visits per year | As agreed in SLA |

| Full service check | Full service + wear part checks | Custom scope of work |

| Ideal balance of cost & reliability | Maximum uptime for critical lines | Complete flexibility & guaranteed response times |

All plans include a full Service Report with recommendations, plus a Preventative Maintenance Checklist you can use in-house.

Brands

We Service

Brands We Service

Lantech Machine Servicing

Robopac Machine Servicing

SIAT Machine Servicing

We also service IBIS, ITW MIMA, Technowrapp, Edda, Spinny, Orbitwrap, Atlanta Stretch and many more.

Semi-automatic and fully automatic pallet wrappers, including rotary arms, ring wrappers, and robots — all covered.

Looking for a brand-specific service? Contact us!

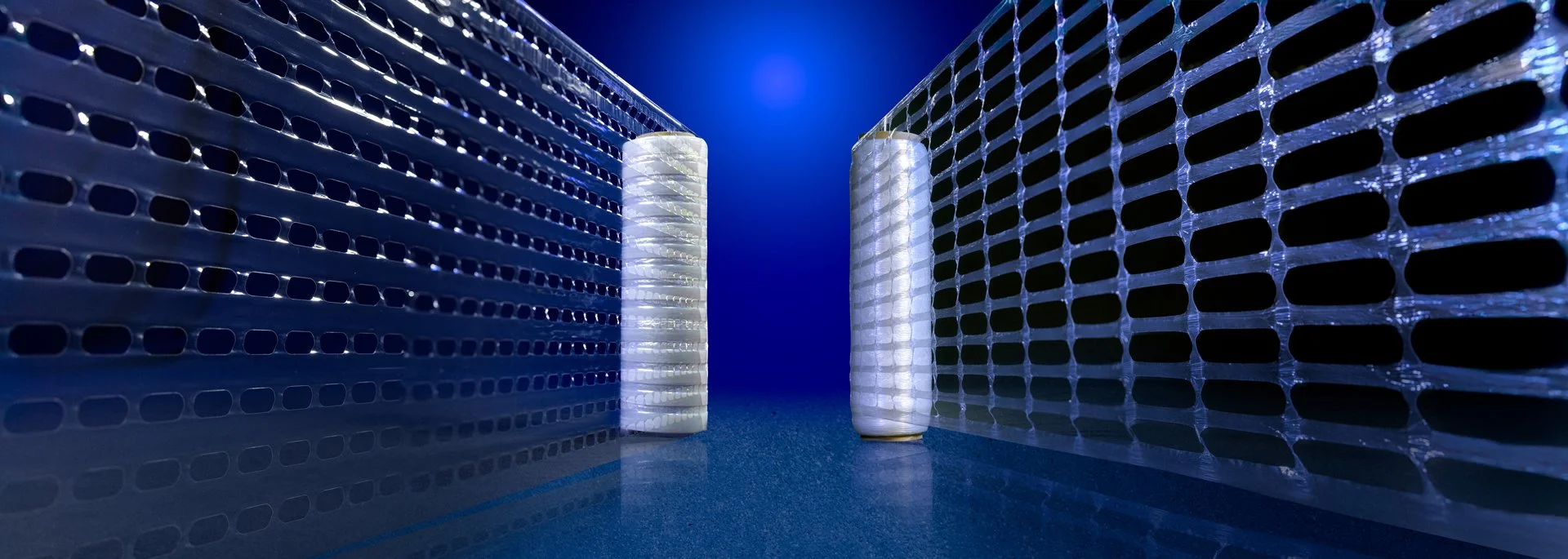

Save Film &

Reduce Costs

Servicing Saves More Than Just Breakdowns

Servicing your pallet wrapping machine doesn’t just prevent downtime — it can deliver major savings on film usage and wrapping costs. When a pallet wrapper isn’t calibrated correctly, it may:

- ✓ Fail to pre-stretch film properly, leading to unnecessary waste

- ✓ Apply too many layers of film, adding cost without improving load stability

- ✓ Cause poor tension control, increasing the risk of unstable pallets and product damage

By investing in our service packages, many businesses see film savings of 10–30%. That means less wasted plastic, lower spend on consumables, and a more sustainable wrapping process — without compromising load security.

💡 Real Savings Example

If you spend £10,000 annually on stretch film, correct application could save you over £3,000.

👉 Reduced operating costs, improved efficiency, and a greener supply chain.

| Uncalibrated Machine | Serviced Machine |

|---|---|

| Wasted film & high costs | 10–30% film savings |

| Poor load stability | Secure, stable pallets |

| Frequent rewraps & rejects | Efficient, first-time wrapping |

Why Choose

Excelerate?

Why Companies Choose Excelerate

- ✓ Expert Engineers – UK trained, multi-brand experienced

- ✓ Fast Response – nationwide coverage, avg. 48hr response

- ✓ OEM Parts – only genuine or approved replacements used

- ✓ Transparent Pricing – no hidden fees, full quote upfront

- ✓ Trusted by Industry – logistics, food & manufacturing

Our engineers are expertly trained in their field and certified by leading UK bodies — ensuring safe, reliable and professional servicing every time.

FAQ

Some Frequently Asked Questions

Contact Our

Service Team

Keep your pallet wrapping and packaging machines running smoothly

- 📞 (UK) 01604 644100

- 📧 service@excelerateltd.com

- 📍 Excelerate Ltd, 1 Newton Close, Park Farm Industrial Estate, Wellingborough, NN8 6UW

- ✅ Contact form for a free, no-obligation quotation